Product characteristics:

High performance pure epoxy polymerization

Excellent corrosion resistance

Excellent mechanical properties

Excellent scratching resistance

High activity, high requirements on storage environment

Typical usage:

Drink water pipe

Fire pipeline

Petroleum and natural gas pipeline

Mine antistatic pipeline

Electronic insulation components

Valve

Steel bar

Special properties:

Antistatic

Flame retardant

High anti-corrosion

Weather resistant

High temperature resistant

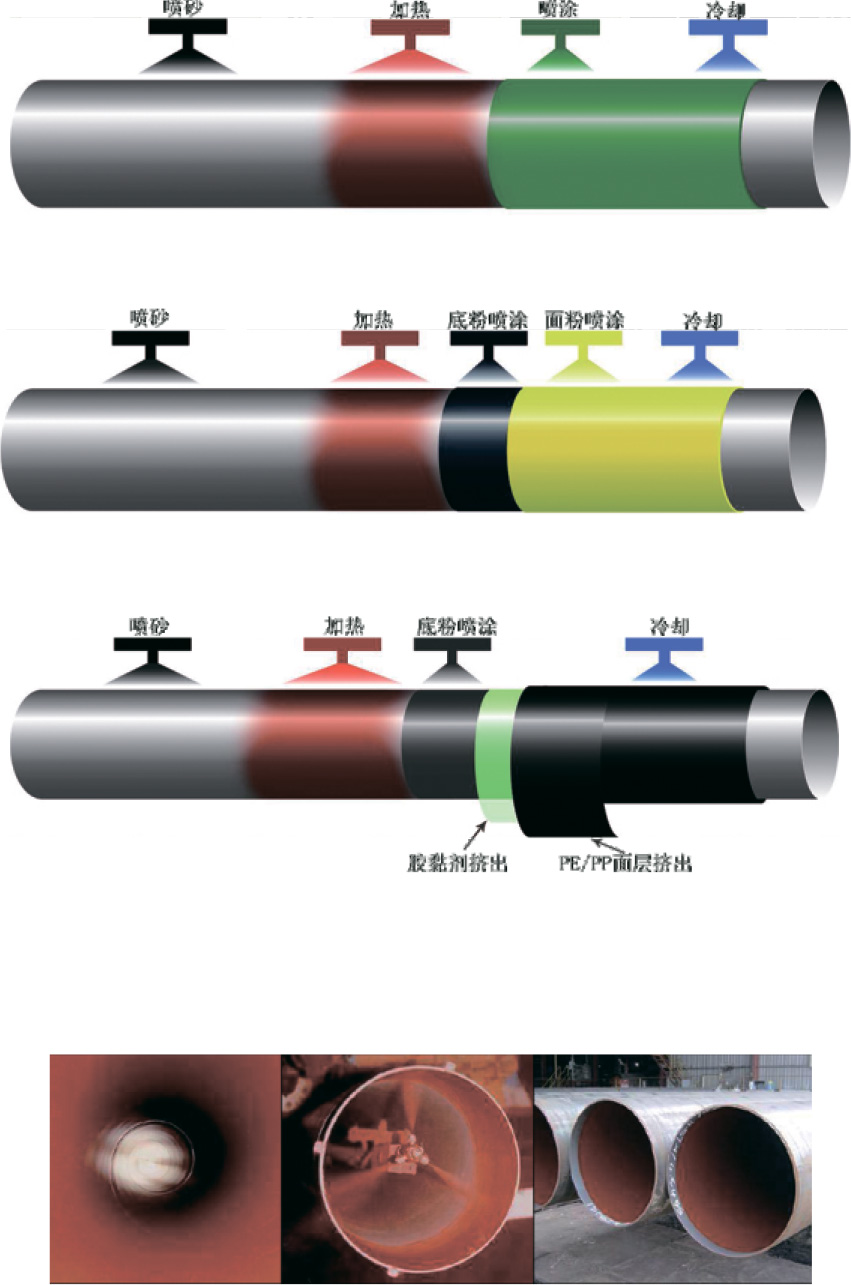

It is the most economical coating for general pipeline construction to coat the pipeline with epoxy powder coating for single layer, which has good adhesion to metal substrates, strong resistance to cathodic disbondment, corrosion resistance and mechanical properties.

It has high cross-linking density of epoxy powder at the bottom and features good anti-corrosion performance to coat the pipeline with epoxy powder coating for double layers. Different systems can be selected for the top powder coating to improve the scratch resistance, skid resistance, flexibility and weather resistance of the coating. Compared with single-layer outer spraying, it features better performance and can be applied to pipelines with special requirements such as high anti-corrosion, crossing and open air.

The pipeline three-layer outer coating system combines FBE and PE/PP. The epoxy powder primer prevents cathodic disbondment. The copolymer adhesive makes the epoxy powder coating primer form strong bond with the outer layer PE / PP, the PE/PP layer is the tough and flexible coating with significant resistance to mechanical damage. The three-layer system gives the coating excellent corrosion resistance, while improving scratch resistance, weather resistance, and flexibility. It is suitable for pipelines with high anti-corrosion requirements and pipelines passing through the walls.

Mikevis pipe inner coating powder features internal and external spraying, roller coating, suction coating and other methods according to the actual situation of the customer. The coating has good corrosion resistance and abrasion resistance to protect the inner and outer substrate of the pipe, prevent the pipeline from corrosion and wear when conveying oil, gas, water, mud and other substances.

Mikevis functional powder coating can not only be used for pipeline protection, but also widely used in pipe fittings, steel bars, high anti-corrosion machine tools, electronic insulation equipment, etc. It can be adjusted according to the actual needs of customers to meet special performance requirements such as high corrosion resistance, antistatic, flame retardancy, high temperature resistance.

Spray process:

Various coating methods such as internal and external spraying, internal suction coating, roll coating, dip coating, etc. can be used.

See Curing Instructions for corresponding model for curing conditions

Standard packaging:

25Kg carton lined with plastic bag

Storage:

Store in the ventilated place below 25 ℃ without direct sunlight, keep away from fire source, effective storage period is 12 months;

Safety:

Powder coating does not contain toxic substances, and no toxic gas is generated during production, storage, transportation and use. However, during use, the operator should wear dust mask, protective glasses and protective clothing to avoid inhalation or direct contact with the powder for a long time, and fire and static sparks should be prohibited during use.

Precautions:

There is a slight difference in color and effect between laboratory color matching and actual production;

Do not mix this product with other powders;

The base material must be properly cleaned and pre-treated before use;

Spray with manual or automatic electrostatic spray gun, please inform in advance if using friction gun for spraying;

The recommended coating film thickness is 60-80um, which can be adjusted appropriately according to the shape of the coated workpiece and regulations.

028-88337056

028-88337056

川公网安备 51012902000062号

川公网安备 51012902000062号