Product characteristics:

Weather-resistant polyester resin/ TGIC polymerization

Meet AAMA 2604 standard

15-year film integrity and color integrity

High storage stability

Good color batch stability

Avoid re-coating, which will cause the coating performance to decrease

Typical usage:

High performance protection in building field

Metal curtain wall panel

Exterior wall

Window frame

Color and Appearance:

Plane high gloss: 70-80°

Plane dull:40-70°

Plane low gloss:20-40°

Sand texture / metal effect

Color:Grey, brown, black, white series

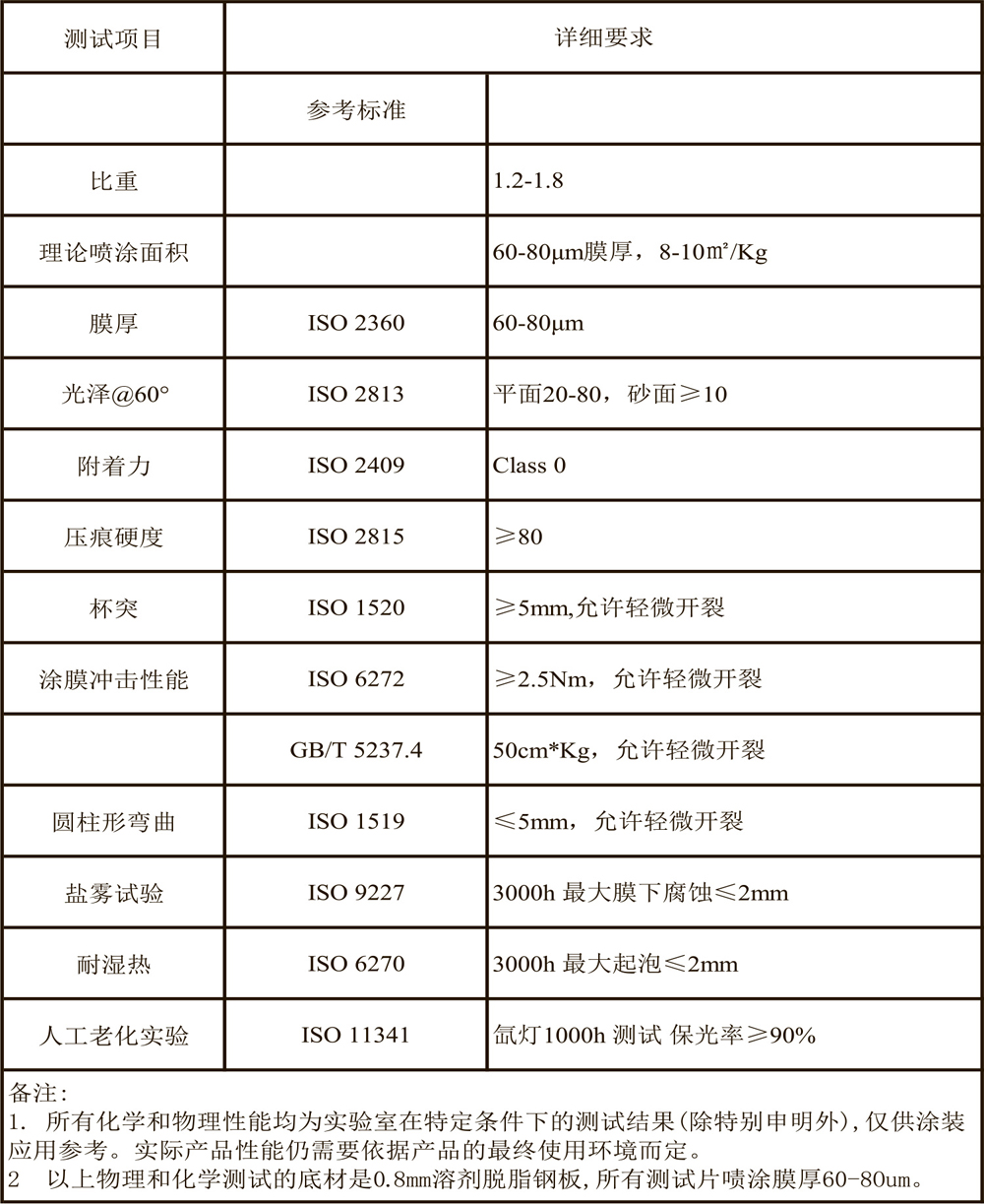

Performance parameters:

Base material and pre-treatment:

Steel: Degreased, phosphated

Aluminum: Chromate-free passivated

Galvanized base material: Phosphated, clean

Spray process:

Corona electrostatic spraying

Friction electrostatic spraying

Curing conditions:

Suggested various curing methods: backing with oven, infrared heating, thermal convection

Limitation: By-products of baking combustion in gas stoves may cause severe changes in coating color

Workpiece temperature 200 ℃/ 10-15min

Standard packaging:

25Kg carton lined with plastic bag

Storage:

Store in the ventilated place below 30 ℃ without direct sunlight, keep away from fire source, effective storage period is 12 months;

For products with gloss below 40°, the effective storage period is 6 months @ 30 °C

Safety:

Powder coating does not contain toxic substances, and no toxic gas is generated during production, storage, transportation and use. However, during use, the operator should wear dust mask, protective glasses and protective clothing to avoid inhalation or direct contact with the powder for a long time, and fire and static sparks should be prohibited during use.

Precautions:

There is a slight difference in color and effect between laboratory color matching and actual production;

Do not mix this product with other powders;

The base material must be properly cleaned and pre-treated before use;

Spray with manual or automatic electrostatic spray gun, please inform in advance if using friction gun for spraying;

The recommended coating film thickness is 60-80um, which can be adjusted appropriately according to the shape of the coated workpiece and regulations.

028-88337056

028-88337056

川公网安备 51012902000062号

川公网安备 51012902000062号